|

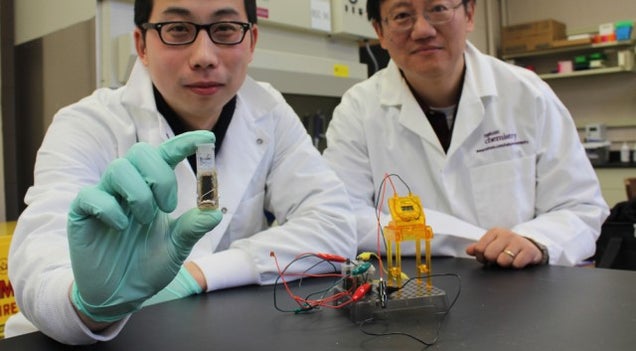

| SYNTHETIC biology—the technique of moving genes from creature to creature not one at a time, but by the handful—promises much but has yet to deliver. Someone who believes it can, though, is Christina Smolke of Stanford University. And, as she and her colleagues write in Nature Chemical Biology, they think they now know one way that it might. |

Image Source: economist.com

To do so, her team added three crucial poppy genes to some yeast cells. When provided with the appropriate chemical precursor, the modified yeast cranked out morphine and another opiate, codeine. And when one of the poppy genes was itself replaced by two genes from Pseudomonas putida, a soil bacterium, the yeast made oxycodone and hydrocodone too. Though this prototype yeast was not particularly efficient, some further tweaking converted it into a veritable drug factory—capable of cooking up 131mg of opioids (the equivalent of about 26 medical doses of diamorphine) per litre of culture over a four-day manufacturing cycle.

Single spies v battalions

Conversely, some drugs—penicillin, for example—are the natural products of unmodified micro-organisms. The pathways that make these non-protein molecules have many steps, sometimes dozens, each controlled by a particular enzyme. What Dr Smolke has done is to assemble appropriate pathways by transferring the genes for each of the enzymes involved.

The job is not yet finished. At the moment, her modified yeast has to be fed with a precursor chemical called thebaine, and this still has to be extracted from poppies. She is, therefore, now trying to coax some yeast into producing thebaine as well. She is nearly there. In previous work, published in 2008, she engineered yeast capable of synthesising a molecule that was two steps removed from thebaine.

If Dr Smolke succeeds, and the technology is commercialised, opiates will join an antimalarial drug called artemisinin as non-protein medicines that can be made by biotechnology. Natural artemisinin is extracted from a species of wormwood that grows in China. The synthetic sort is made by Sanofi, to a recipe devised by Jay Keasling, a researcher at the University of California, Berkeley, and developed by Amyris, a firm he helped to found. And there may be a third drug in the pipeline.

Earlier this year a group led by Bradley Moore of the University of California, San Diego, transferred a cluster of bacterial genes which they suspected might encode the pathway for making an unknown antibiotic into another bacterium, Streptomyces coelicolor. They were right. Their discovery is called taromycin A. In a world crying out for new antibiotics, as bugs develop resistance to old ones, this may prove an important find. And if taromycin A does fulfil its promise then, thanks to Dr Moore, a biofactory that might be used to make it is already up and running.

Businesswoman and environmental advocate Janique Goff supports start-up businesses in the biotechnology industry. Read more related stories on biotechnology and pharma research here.